Effect of H-DLC coatings on direct acting cam-tappet friction forces

DOI:

https://doi.org/10.14295/vetor.v32i1.13417Keywords:

cam-tappet, friction forces, H-DLCAbstract

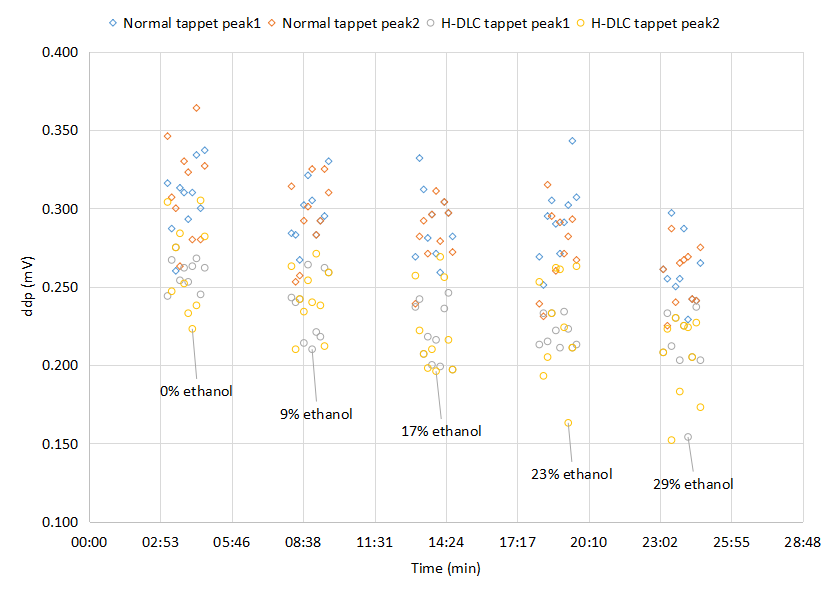

In internal combustion engines, the valvetrain is responsible for up to 25% of the friction losses, at rotational frequencies below 2000 rpm. Important friction losses in valvetrain come from the contact between the cam and the tappet. Despite to manufacturer specifications for the engine lubricant, the lubricant viscosity can be changed under some conditions, affecting the cam-tappet contact forces. Also, the surface conditions of cam and tappet can affect these friction forces. This work presents a bench mono-valve experimental apparatus and results for frictional force investigations, using aged engine lubricant SN5W30, with viscosity modifications. The influence of a tappet crown coated with H-DLC is investigated, comparing to standard tappets. These experiments showed that, under specific experimental conditions, the friction forces between the cam and the tappet are the lowest with H-DLC application, for all lubricant viscosity applied.

Downloads

References

Agência Nacional de Petróleo (in Portuguese), ANP. Available at: http://www.anp.gov.br/producao-de-derivados-de-petroleo-e-processamento-de-gas-natutal/producao-centrais-de-materias-primas-petroquimicas-cpq/gasolina.

K. G. Duleep, “The Benefits of Increasing Fuel Octane Number on Gasoline Engine Efficiency: A Literature Review,” SAE Technical Paper 2017-01-2237, 2017. Available at: https://doi.org/10.4271/2017-01-2237.

K. Holmberg and A. Erdemir, “Global Impact of Friction on Energy Consumption, Economy and Environment,” FME Transactions, vol. 43, no. 3, pp. 181-185, 2015. Available at: https://doi.org/10.5937/fmet1503181H.

A. Ferrarese, “Anéis de Pistão de Baixo Atrito” (in Portuguese), Mahle Metal Leve, 2015.

B. S. Andersson, Paper XVIII (iii) Company Perspectives in Vehicle Tribology – Volvo, Editor(s): D. Dowson, C.M. Taylor, M. Godet, Tribology Series, vol. 18, pp. 503-506, 1991. Available at: https://doi.org/10.1016/S0167-8922(08)70168-8.

Wong, V. W. and Tung S. C, “Overview of automotive engine friction and reduction trends - Effects of surface, material, and lubricant-additive technologies,” Friction, vol. 4, no. 1, pp. 1-28, 2016. Available at: https://doi.org/10.1007/s40544-016-0107-9.

A. Gangopadhyay, D. G. McWatt, R. J. Zdrodowski, S. J. Simko, S. Matera, K. Sheffer, and R. S. Furby, “Valvetrain Friction Reduction through Thin Film Coatings and Polishing,” Tribology Transactions, vol. 55, no. 1, pp. 99-108, 2012. Available at: https://doi.org/10.1080/10402004.2011.636169.

A. R. Schamel, M. Grischke, and R. Bethke, “Amorphous carbon coatings for low friction and wear and bucket tappet valvetrains,” SAE Technical Paper 970004, 1997. Available at: https://doi.org/10.4271/970004.

L. A. Ratamero and V. Ventura, “Fuel Economy Sensitivity Analysis for DLC Coatings on Tappets,” SAE Technical Paper 36-0027, 2018. Available at: https://doi.org/10.4271/2018-36-0027.

A. Dyson and M. A. Naylor, “Application of the Flash Temperature Concept to Cam and Tappet Wear Problems,” Proceedings of the Institution of Mechanical Engineers: Automobile Division, vol. 14, no. 1, pp. 255-280, 1960. Availabe at: https://doi.org/10.1243/PIME_AUTO_1960_000_026_02.

M. Teodorescu, D. Taraza, N. A. Henein, and W. Bryzik, “Experimental analysis of dynamics and friction in valve train systems,” SAE Transactions, vol. 11, sec. 3 (Journal of Engines), pp. 1027-1037, 2002. Available at: https://doi.org/10.4271/2002-01-0484.

C. M. Engler-Pinto, L. de Nadai, and E. Martins, “Analysis of Oil Sump Contamination with Ethanol in Flex Fuel Engines after Crank and Warm-up,” SAE Technical Paper 2009-36-0117, 2009. Available at: https://doi.org/10.4271/2009-36-0117.

A. Gangopadhyay, E. Soltis, and M. D. Johnson, “Valvetrain friction and wear influence of surface engineering and lubricants,” Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, vol. 218, no. 3, pp. 147-156, 2004. Available at: https://doi.org/10.1177/135065010421800302.

M. Calabretta, D. Cacciatore, and P. Carden, “Valvetrain Friction - Modeling, Analysis and Measurement of a High-Performance Engine Valvetrain System,” SAE International Journal of Engines, vol. 3, no. 2, pp. 72-84, 2010. doi:10.4271/2010-01-1492, 2010. Available at: https://doi.org/10.4271/2010-01-1492.

ABNT NBR 6601:2012, “Light road vehicles - Determination of hydrocarbon, carbon monoxide, nitrogen oxide, carbon dioxide and particulate material on exhaust gas,” (in Portuguese), 2012.

H. L. Costa and H. Spikes, “Impact of ethanol on the formation of antiwear tribofilms from engine lubricants,” Tribology International, vol. 93, part A, pp. 364-376, 2016. Available at: https://doi.org/10.1016/j.triboint.2015.09.021.

Downloads

Published

Versions

- 2022-07-29 (2)

- 2022-07-15 (1)