Hardness and Texture of Electrolytic Copper Processed by ECAP at Ambient and Warm Temperature

DOI:

https://doi.org/10.14295/vetor.v31i2.13743Keywords:

Copper, ECAP, Crystallographic Texture, Dislocation Density, MicrohardnessAbstract

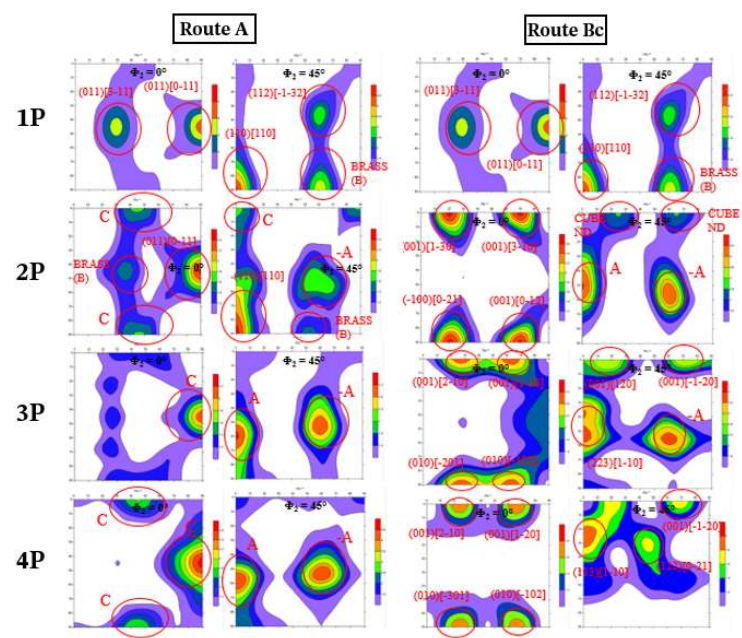

Among several severe plastic deformation (SPD) methods, the Equal Channel Angular Pressing (ECAP) process is one of the most popular. This process's main characteristic is producing materials with ultra-fine or nanometric grains. Due to these microstructural changes, it is possible to improve mechanical properties such as strength and ductility. In this perspective, the aim of the present work was to evaluate the variations of the mechanical hardness property associated with microstructural and textural changes of pure copper as a function of its processing by SPD via ECAP. For this, the material was submitted to four passes through routes A (the sample is repetitively pressed without any rotation between each pass) and Bc (the sample is rotated in the same sense by 90° between each pass) at cold and warm temperatures. Through the obtained result, it was verified that the ambient temperature of the Bc route was the one that promoted greater homogeneity in the microstructure and weakening of the texture after the fourth pass. On the other hand, warm processing of copper by ECAP promoted a softening of the samples and a homogeneous distribution of hardness in both routes.

Downloads

References

G. Faraji, H. S. Kim and H. T. Kashi, “Mechanical properties of ultrafine-grained and nanostructured metals,” in Severe Plastic Deformation, Elsevier, 2018, p. 223-257. Available at: https://doi.org/10.1016/b978-0-12-813518-1.00007-2

T.G. Langdon, “Processing by severe plastic deformation: historical developments and current impact,” Materials Science Forum, vol. 667-669, pp. 9-14, 2010. Available at: https://doi.org/10.4028/www.scientific.net/msf.667-669.9

S. N. Alhajeri, N. Gao, T. G. Langdon, “Hardness homogeneity on longitudinal and transverse sections an aluminum alloy processed by ECAP”, Materials Science and Engineering A, vol. 528, pp. 3833-3840, 2011. Available at: https://doi.org/10.1016/j.msea.2011.01.074

A. T. Vijayashakthivel, T. N. Srikantha Dath and R. Krishnamurthy, “Response for copper to Equal Channel Angular Pressing with different processing temperature,” Procedia Engineering, vol. 97, pp. 56-63, 2014. Available at: https://doi.org/10.1016/j.proeng.2014.12.224

S. Ranjbar Bahadori, K. Dehghani and F. Bakhshandeh, “Microstructure, texture and mechanical properties of pure copper processed by ECAP and subsequent cold rolling,” Materials Science and Engineering: A, vol. 583, pp. 36-42, 2013. Available at: https://doi.org/10.1016/j.msea.2013.06.061

K. Neishi, Z. Horita and T. G. Langdon, “Achieving superplasticity in a Cu–40%Zn alloy through severe plastic deformation,” Scripta Materialia, vol. 45, no. 8, pp. 965–970, 2001. Available at: https://doi.org/10.1016/s1359-6462(01)01119-8

G. F. Vander Voort, Metallography: principles and practice. 2nd ed. New York: McGraw-Hill, 1984.

J. S. Kallend and G. J. Davies, “The development of texture in copper and copper-zinc alloys,” Texture, vol. 1, no. 1, pp. 51-69, 1972. Available at: https://doi.org/10.1155/tsm.1.51

R. Z. Valiev and T. G. Langdon, “Principles of equal-channel angular pressing as a processing tool for grain refinement,” Progress in Materials Science, vol. 51, no. 7, pp. 881-981, 2006. Available at: https://doi.org/10.1016/j.pmatsci.2006.02.003

M. Y. Alawadhi, S. Sabbaghianrad, Y. Huang and T. G. Langdon, “Direct influence of recovery behavior on mechanical properties in oxygen-free copper processed using different SPD techniques: HPT and ECAP,” Journal of Materials Research and Technology, vol. 6, no. 4, pp. 369-377, 2017. Available at: https://doi.org/10.1016/j.jmrt.2017.05.005

M. Y. Alawadhi, S. Sabbaghianrad, Y. Huang, and T. G. Langdon, “Evaluating the paradox of strength and ductility in ECAP at ambient temperature ultrafine-grained oxygen-free copper processed by ECAP at ambient temperature,” Materials Science and Engineering: A, vol. 802, article 140546, 202’. Available at: https://doi.org/10.1016/j.msea.2020.140546

H. Wen, Y. Zhao, T. D. Topping, D. Ashford, R. B. Figueiredo, C. Xu, T. G. Langdon, E. J. Lavernia, “Influence of pressing temperature on microstructure evolution and mechanical behavior of ultrafine-grained Cu processed by Equal-Channel Angular Pressing,” Advanced Engineering Materials, vol. 14, no. 3, pp. 185-194, 2012. Available at: https://doi.org/10.1002/adem.201100080

M. P. P. Leis, S. S. Carvalho, T. G. Sousa, S. I. V. Santana and L. P. Branda, “Comparative study by TEM, EBSD and microhardness of the microstructure of copper wiredrawn at 77 K and 295 K,” Tecnologia em Metalurgia, Materiais e Mineração, vol. 16, no. 2, pp. 279-283, 2019. Available at: https://doi.org/10.4322/2176-1523.20191731

T. G. Sousa, V. L. Sordi and L. P. Brandão, “Dislocation density and texture in copper deformed by cold rolling and Ecap,” Materials Research, vol. 21, no. 1, 2018. Available at: https://doi.org/10.1590/1980-5373-mr-2017-0515

I. L. Dillamore, R. E. Smallman and W. T. Roberts, “A determination of the stacking-fault energy of some pure FCC metals,” The Philosophical Magazine: A Journal of Theoretical Experimental and Applied Physics, vol. 9, no. 99, p. 517-526, 1964. Available at: https://doi.org/10.1080/14786436408222963

Y. Huang, S. Sabbaghianrad, A. I. Almazrouee, K. J. Al-Fadhalah, S. N. Alhajeri and T. G. Langdon, “The significance of self-annealing at room temperature in high purity copper processed by high-pressure torsion,” Materials Science and Engineering: A, vol. 656, pp. 55-66, 2016. Available at: https://doi.org/10.1016/j.msea.2016.01.027

F. Liu, H. Yuan, J. Yin and J. T. Wang, “Influence of stacking fault energy and temperature on microstructures and mechanical properties of fcc pure metals processed by equal-channel angular pressing,” Materials Science and Engineering: A, vol. 662, pp. 578-587, 2016. Available at: https://doi.org/10.1016/j.msea.2016.03.022

A. Zi, “Pure copper processed by extrusion preceded equal channel angular pressing,” Materials Characterization, vol. 61, no. 2, pp. 141-144, 2010. Available at: https://doi.org/10.1016/j.matchar.2009.11.03

A. M. Kliauga, W. R. Sussai, M. Ferrante, V. L. Sordi, R. E. Bolmaro, “Texture and lankford factor of AA1050 alloy deformed by angular channel extrusion and heat treated”, pp. 1214-1223, in 67th ABM international congress, 2012.

O. F. Higuera and J. M. Cabrera, “Texture analysis in ultrafine grained coppers processed by equal channel angular pressing,” Materials Research, vol. 16, no. 3, pp. 619–624, 2013. Available at: https://doi.org/10.1590/s1516-14392013005000032

A. I. Alateyah, M. M. Z. Ahmed, Y. Zedan, H. A. El-Hafez, M. O. Alawad, and W. H. El-Garaihy, “Experimental and numerical investigation of the ECAP processed copper: microstructural evolution, crystallographic texture and hardness homogeneity,” Metals, vol. 11, no. 4, pp. 607, 2021. Available at: https://doi.org/10.3390/met11040607

A. P. Gulháev, Metals and their Alloys – Volume 1 – Structures, properties and industrial application (General and structural metallography). Moscow: Mir, 1981.

F. Liu, T. Fa, P. H. Chen and J. T. Wang, “Steady-state characteristics of FCC pure metals processed by severe plastic deformation: experiments and modelling,” Philosophical Magazine, vol. 100, no. 1, pp. 62–83, 2020. Available at: https://doi.org/10.1080/14786435.2019.1671621

A. Rohatgi, K. S. Vecchio and G. T. Gray, “The influence of stacking fault energy on the mechanical behavior of Cu and Cu-Al alloys: Deformation twinning, work hardening, and dynamic recovery,” Metallurgical and Materials Transactions A, vol. 32, no. 1, pp. 135–145, 2001. Available at: https://doi.org/10.1007/s11661-001-0109-7

G. Carro, A. Muñoz, B. Savoini, M. A. Monge and R. Pareja, “Processing, microstructure and mechanical characterization of dispersion strengthened Cu-1%Y,” Fusion Engineering and Design, vol. 138, pp. 321–331, 2019. Available at: https://doi.org/10.1016/j.fusengdes.2018.11.058